In the traditional fabric industry, the cutting and cutting process usually relies on manual tools or traditional cutting machines. However, with the advancement of technology, a new cutting technology - laser cutting - has gradually entered our sight. This technology, with its efficient, precise, and environmentally friendly characteristics, is changing the production mode of the fabric industry.

The basic principle of laser cutting is to use a high-energy laser beam to irradiate the surface of the material, and through the focused laser beam, a precise cutting line can be burned on the material. When the laser beam leaves the focus, its energy is absorbed by the material, forming a small hole. When the material passes through this hole, the small hole forms a notch. By adjusting the position and intensity of the laser beam, the shape and size of the cutting can be precisely controlled.

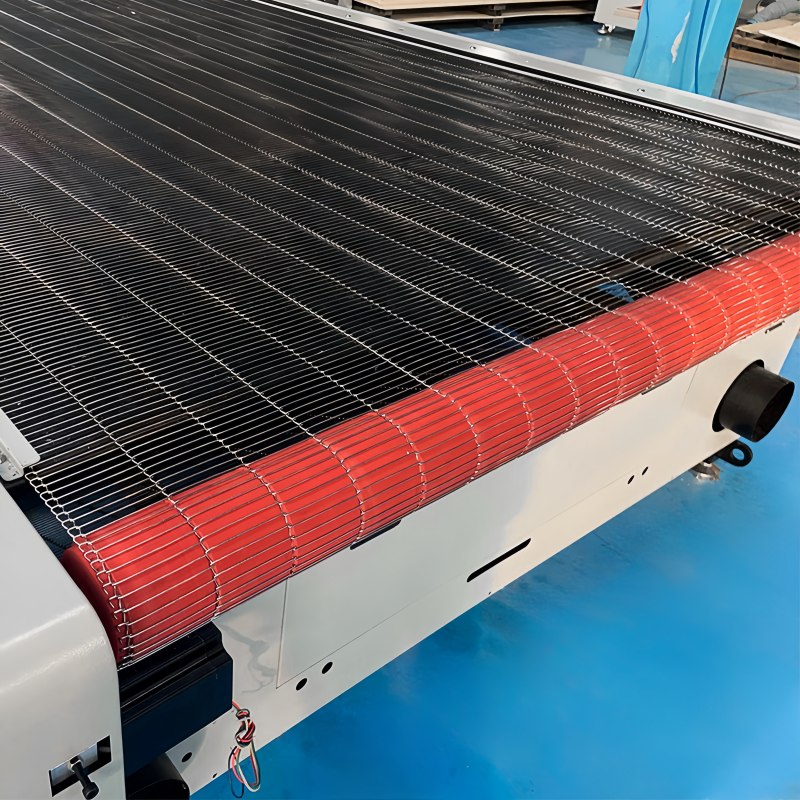

In the fabric industry, the application of laser cutting machines is mainly reflected in the following aspects:

1. Efficiency: Compared to traditional scissors or saw blade cutting, laser cutting has a much faster speed. Due to the fact that laser beams can complete cutting in a few seconds, production efficiency is greatly improved. In addition, laser cutting can also be automated without the need for manual intervention.

2. Precision: The precision of laser cutting is very high, with smooth and burr free cutting edges. This is very important for producing high-quality fabric products. For example, precise cutting is essential when making high-end customized clothing and home textiles.

3. Environmental protection: Traditional cutting methods generate a large amount of waste and noise, while laser cutting does not. Due to the fact that the laser beam is focused, it can reduce material waste. In addition, the noise generated by laser cutting machines during operation is much lower than that of traditional cutting machines.

4. Flexibility: Laser cutting machines have a wide range of applications and can cut materials of various shapes and sizes. This enables fabric manufacturers to adapt to constantly changing market demands and meet the diverse customization needs of customers.

However, despite the numerous advantages of laser cutting machines, we must also recognize some of the challenges that may be encountered in their application process. For example, high equipment and maintenance costs may increase production costs. In addition, it is also very important to provide appropriate training to operators to ensure safe operation.